Save up to $50 this Labor Day Weekend. Details Here .

Fecha de entrega estimada

Métodos de pago

Detalles del producto

Oz Levantando carros de haz de empuje resistente a chispas

El levantamiento de Oz trolley de haz de empuje resistente a chispas está diseñado para un uso seguro en atmósferas potencialmente explosivas. Cuando se trabaja en zonas explosivas, existen pautas y requisitos extremadamente estrictos para el equipo que utiliza. Estos carros de haz están diseñados para su uso con polipastos manuales o alimentados.

Los carros de haz de empuje resistente a la chispa de Oz Lifting Products se fabrican de conformidad con el estándar a prueba de explosión de la UE ATEX94/9/CE y la Directiva de maquinaria 2006/42/CE. El nivel a prueba de explosión puede alcanzar: EX II2 GD C IIIC T135 ° C. Son adecuados para atmósferas potencialmente explosivas, incluidas la zona 1 y 2 (gas), así como la zona 21 y 22 (polvo).

CARACTERÍSTICAS

- Recubrimiento contra el spark

- Ruedas de carro chapada de cobre y bala de elevación

- Etiquetas de identificación de cobre remachadas

- Se adapta a la mayoría de las vigas I, S y W y W

- Ruedas de carrito de rodamiento de bolas de precisión

- Placa anti-gota

- Certificado de prueba individual y número de serie

Estándares - CE, ATEX - 94/9/CE (EX II 2 GD C IIC T4 IIIC T135 ° C), AS1418.2, ASME B30.11, ASME B30.16 (para usar con polos manuales o para polipasos potenciados)

| OZSR05PBT | OZSR1PBT | OZSR2PBT | OZSR3PBT | OZSR5PBT | OZSR10PBT | ||

| Capacidad (toneladas) | .5 | 1 | 2 | 3 | 5 | 10 | |

| Curva de radio mínimo (FT) | 2.62 | 3.28 | 3.61 | 4.26 | 4.59 | 6.56 | |

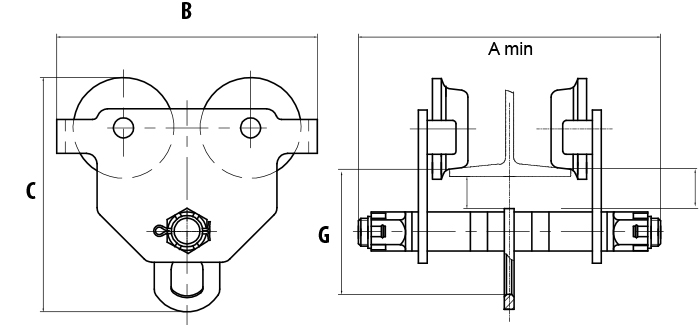

| Dimensiones del producto (IN) | A | 11.61 | 12.24 | 16.89 | 17.52 | 17.99 | 19.29 |

| B | 7.83 | 9.69 | 10.87 | 13.07 | 14.84 | 16.69 | |

| C | 7.36 | 8.74 | 10.34 | 12.17 | 13.90 | 15.59 | |

| GRAMO | 4.13 | 4.92 | 5.91 | 6.73 | 7.72 | 7.48 | |

| Espesor de brida máxima (in) | mi | 1.18 | 1.50 | 1.50 | 1.57 | 1.65 | 1.77 |

| Ancho de brida ajustable (IN) | 1.97-8.00 | 2.50-8.00 | 3.64-12.00 | 3.94-12.00 | 4.50-12.00 | 4.88-12.00 | |

| Peso neto (LBS) | 16 | 23 | 42 | 64 | 95 | 196 |

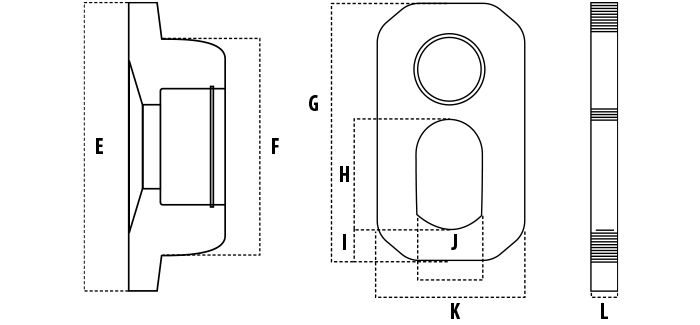

Dimensiones de rueda y fianza.

| TAMAÑO | 0.5t | 1T | 2t | 3T | 5T | 10t |

| E (en) | 3.11 | 3.74 | 4.25 | 5.12 | 5.63 | 6.93 |

| F (en) | 2.17 | 2.68 | 3.15 | 3.94 | 4.33 | 5.35 |

| Ginebra) | 3.50 | 4.02 | 5.12 | 6.02 | 7.24 | 7.68 |

| H (en) | 1.26 | 1.58 | 2.05 | 2.48 | 2.95 | 4.72 |

| Yo (en) | 0.57 | 0.59 | 0.71 | 0.87 | 1.18 | 1.77 |

| J (en) | 0.98 | 1.18 | 1.50 | 1.58 | 1.97 | 2.84 |

| Familiares) | 1.97 | 2.44 | 2.95 | 3.35 | 4.25 | 11.42 |

| L (en) | 0.24 | 0.32 | 0.47 | 0.55 | 0.63 | 0.98 |

- Al seleccionar una opción, se actualiza toda la página.

- Se abre en una nueva ventana.